Introduction

The Airship is a project to build an autonomous vehicle lifted by volatile gas, complete with a dedicated flight control station system and docking station. It is also the largest project undertaken by SSA SpaceCoffee to date.

The idea behind the project is to make an advancement air transport by utilizing a vehicle that is lighter than air. Since the discontinuation of airships, the demand for sustainable, alternative transport solutions in the 21st century has revived interest in research into such flying systems. The airship we have designed and constructed is to be relatively small, with a payload capacity of up to 5 kg. Its main purpose is to transport cargo over short distances. The success of the project demonstrates the potential for further development and wider use of such airships as an alternative to transport drones and other devices with limited payload capacity and short operating times. Their long ascent time, low energy consumption, and minimal infrastructure requirements are a great advantage, as is their effectiveness in favorable conditions with light winds.

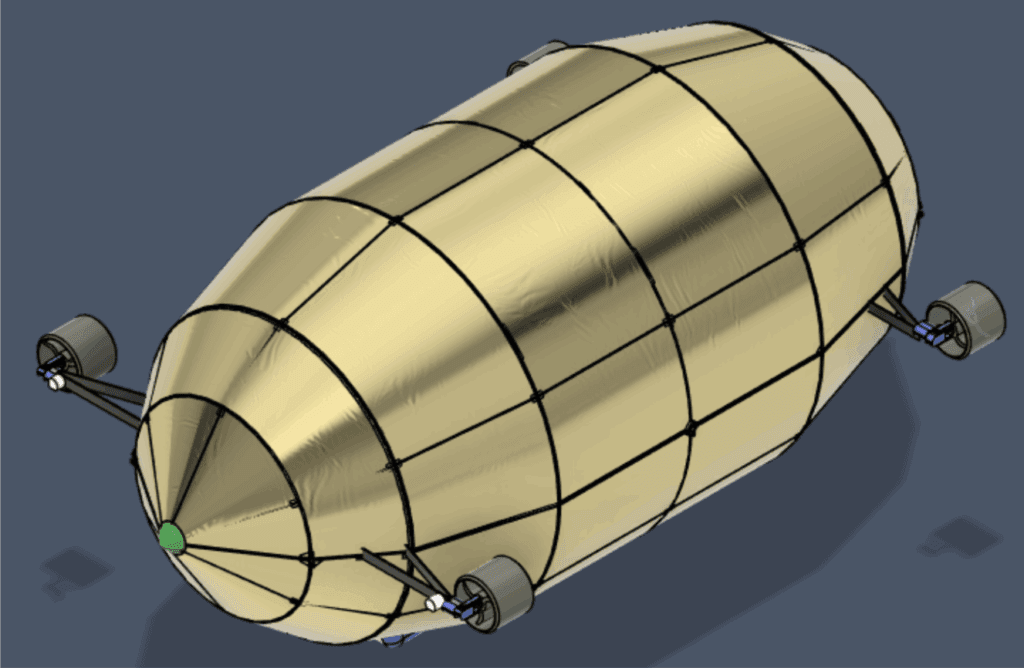

Construction design

The aircraft's design is intended to maximize lift efficiency while ensuring durability, modularity, and low overall weight. The frame supporting the propulsion system, electronic components, and cargo attachment mechanism is constructed from durable carbon rods, wooden elements, and 3D-printed parts, such as fasteners. This allows for precise adjustments during the testing phase. It also makes prototyping affordable. The gondola basket under the plating contains the main computing unit (Raspberry Pi 5), batteries, and main sensors. Its design allows quick access to components. The airship will float in the air thanks to stratospheric balloons filled with carrier gas, which are mounted on the frame under the skin. The plating is designed to reduce the risk of static electricity build-up on the exterior surfaces of the airship. Hydrogen will be used as the lifting gas during testing, but stable helium will be required for public presentations.

To complete the construction, it was necessary to determine the weight distribution and center of gravity stabilization, as both factors are critical to achieving flight stability and ensuring responsive autonomous navigation. To account for the expansion and contraction of gas in the airship during flight, the design also incorporated a flexible mounting system between the skin and the rigid body.

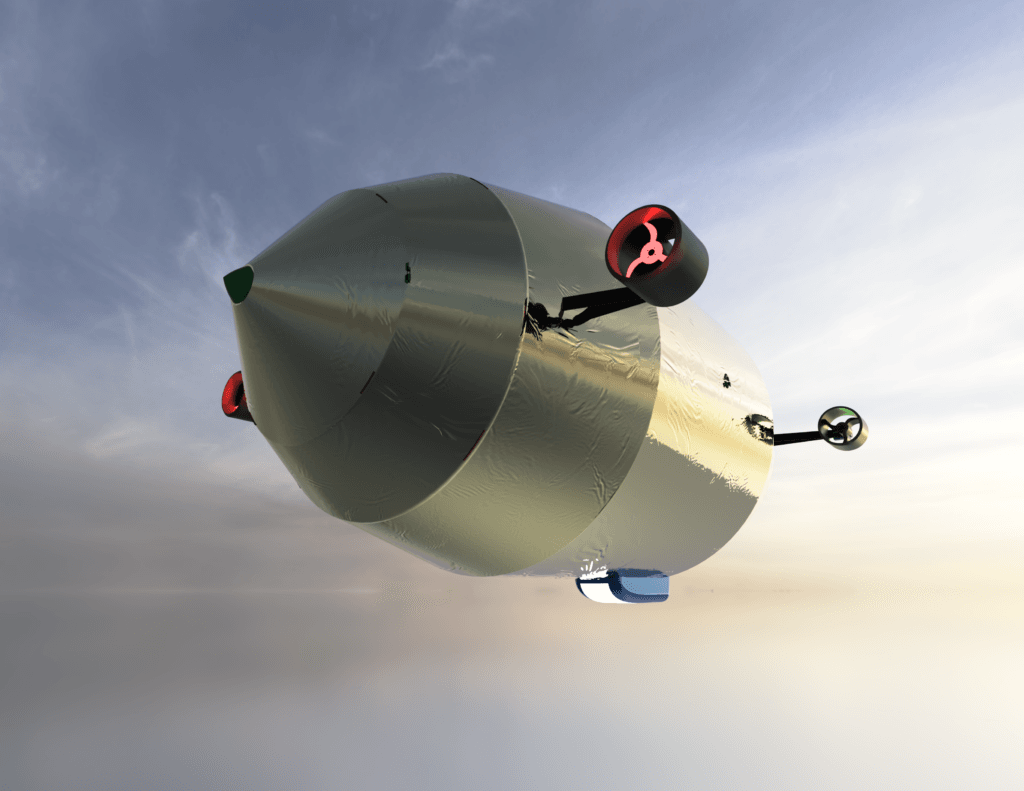

Propulsion system

The propulsion system will ultimately be integrated with the autonomy system. Each motor assembly consists of two servomotors connected by lightweight brackets printed using 3D technology, with an electric motor at the end.

The brackets are connected in such a way as to allow independent rotation of the motor in two axes, which provides the operator with a high degree of maneuverability and precision. This arrangement also allows for operation in enclosed spaces or in conditions requiring constant adjustments, e.g., facing angled winds.

Focusing on the vehicle's purpose as a lightweight means of transporting cargo weighing up to 5 kg, propulsion components were selected to ensure a balance between thrust and energy consumption. The system consists of multiple electric motors, arranged in such a way as to ensure multidirectional controllability and stable flight in low wind conditions. Specially designed mounting arms, 3D-printed from lightweight composite filament, provide support for the motors. The propulsion system must be tightly integrated with the aircraft's control architecture, allowing for a transition between manual and fully autonomous flight modes. The propulsion units are powered by lithium-ion batteries.

During flight, the aircraft must be actively stabilized, especially in response to changes in position, wind conditions, and load distribution. To achieve this, the propulsion system dynamically adjusts the thrust level based on data from on-board sensors—positioning modules and inertial data. Coordination is handled by the operating system. Precise control of lift and forward motion is essential for navigation during cargo pickup and delivery.

System operation

The SpaceCoffee airship operates on the basis of an integrated control architecture that combines data collected from sensors, autonomous decision-making, and real-time actuator management. At the heart of the system is a Raspberry Pi 5 microcontroller, which coordinates flight logic, sensor communication, and drive commands. The onboard software includes modules tailored for route planning, obstacle avoidance, altitude control, and landing procedures. Navigation is based on a combination of a LIDAR module, a GPS positioning system, and proximity sensors, allowing the airship to accurately read its position and react dynamically to its surroundings. Control algorithms are implemented with the ability to switch between manual, semi-autonomous, and fully autonomous modes, depending on mission requirements or operator intervention.

All critical telemetry data is transmitted wirelessly to the base station for real-time monitoring and post-mission analysis. To enhance operational safety, redundant communication protocols and a basic fail-safe module are employed, ensuring that the aircraft will perform an emergency landing in the event of a system failure or power loss. Operational protocols and controls form the basis for reliable and repeatable performance.

Autonomous navigation

The autonomous system is being developed to enable fully autonomous flight, eliminating the need for constant human supervision. The key innovation presented in the project is the use of a machine learning model that has been trained to control aircraft navigation and perform basic tasks. The training process focuses on achieving high performance using a minimal set of data, reflecting the real-world constraints of collecting extensive flight data.

Instead of relying solely on rule-based logic, the system is designed to learn and adapt through exposure to selected flight scenarios, enabling it to perform tasks such as following a designated route, avoiding obstacles, and transporting light loads. Training takes place on a dedicated computing unit configured for artificial intelligence tasks, and the final model is then deployed as part of the airship-based system.

Preliminary field tests are planned in favorable weather conditions to verify the model's behavior in a friendly environment. The ultimate goal of the project is to implement an adaptive, learning-based autonomous system. This approach opens the way to further options, such as reinforcement learning in dynamic environments.

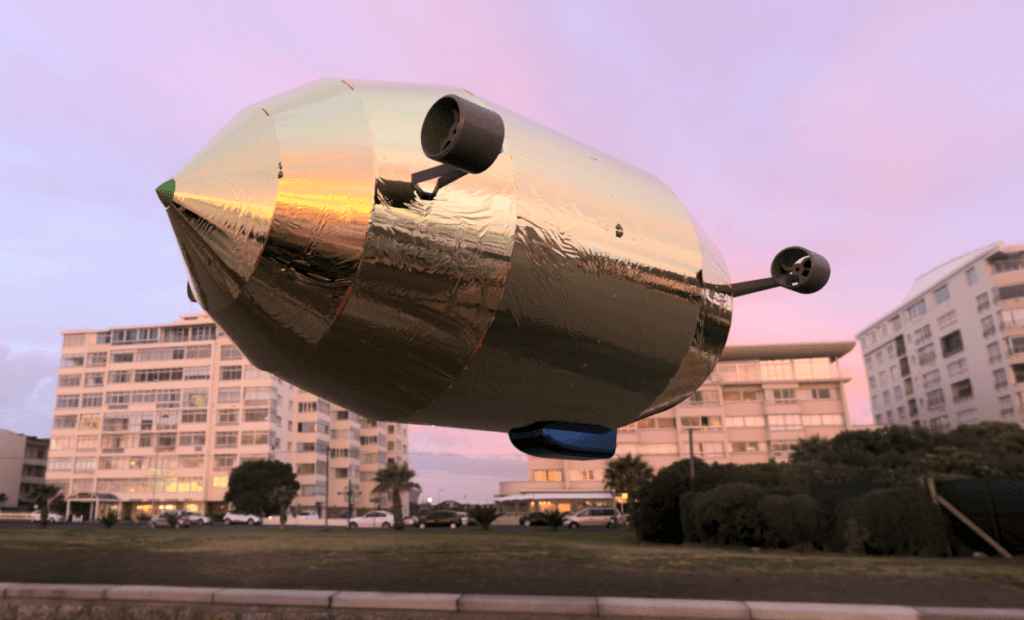

How the Airship was created: gallery

First test flight experience: gallery

The future of the project

The Airship will be further developed in subsequent iterations of the project. A change in design is planned to achieve better balance, including a change in frame size. Thanks to funding for subsequent projects, the autonomy of the navigation system will be intensively developed.